The particle board structure fill with honeycomb paper, convert the 3mm MDF in double side. Going through the short cycle press line, Its functions include sanding and covering, which takes only 80 seconds to finish and it supports double side press for veneer and melamine.

It has 3 layers of color painting, such as base coat and top coat. The speed is 16 to 18 m/min, rolling surface B side first, then A face. The whole working time is 7 minutes and only for parallel parts. It saves time and materials and its utilization can reach 99%.

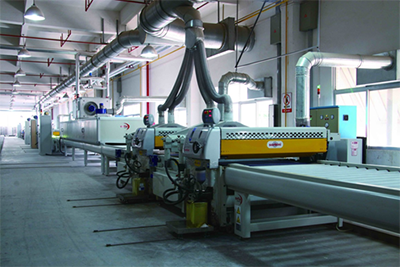

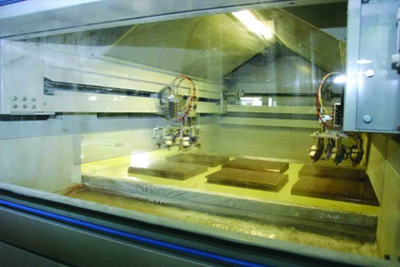

After one move, the panel will entry the Robot Spraying System, this line is for PU painting(polyurethane). It is designed for highlight products (glossy: more than 60 degrees). In order to reduce the dust’s influence for the paint, the workers need to operate in a fully sealed environment. The machine has an anti - pole device, which can remove the particles sticking on the panel. It can take advantage of the manipulator for five surfaces spraying at the same time. The speed is 5 m/min and the maximum stack height is 900mm. The whole working time is 1 hour and 20 minutes. It can be used for arc and parallel parts, including edge and corner with high precision. When finish all the painting process, the products will reach 5 coats paints.